Warning: Do not attempt to troubleshoot refrigerant charge on central air conditioning units unless you are EPA 608 type II Certified.

Warning: Do not attempt to troubleshoot refrigerant charge on central air conditioning units unless you are EPA 608 type II Certified.

This article refers to troubleshooting refrigerant charge on 410a and R22 residential air conditioning systems. Although many of the principles will carry over to other types of refrigerants and drop-ins. I will be sharing a pressure chart that may help you troubleshoot low pressure symptoms, high pressure symptoms. As well as other potential problems you may run into when trying to get your r410a or r22 systems to normal operating pressures.

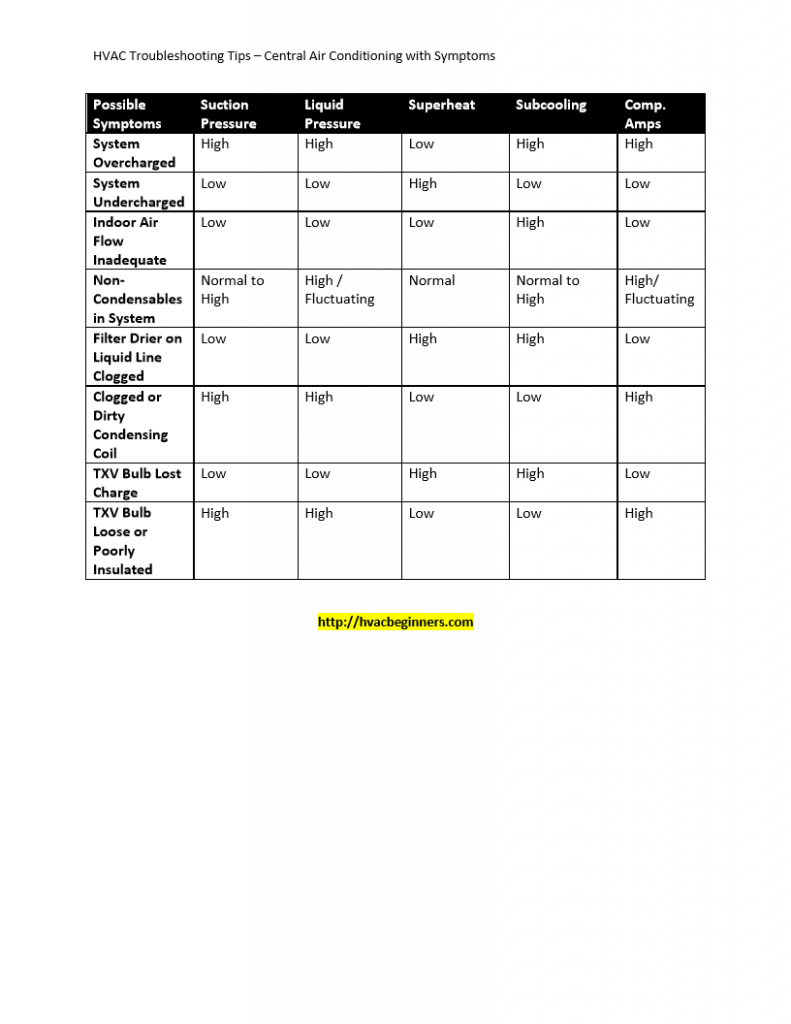

HVAC Troubleshooting Chart with Superheat, Subcooling and Compressor Amps

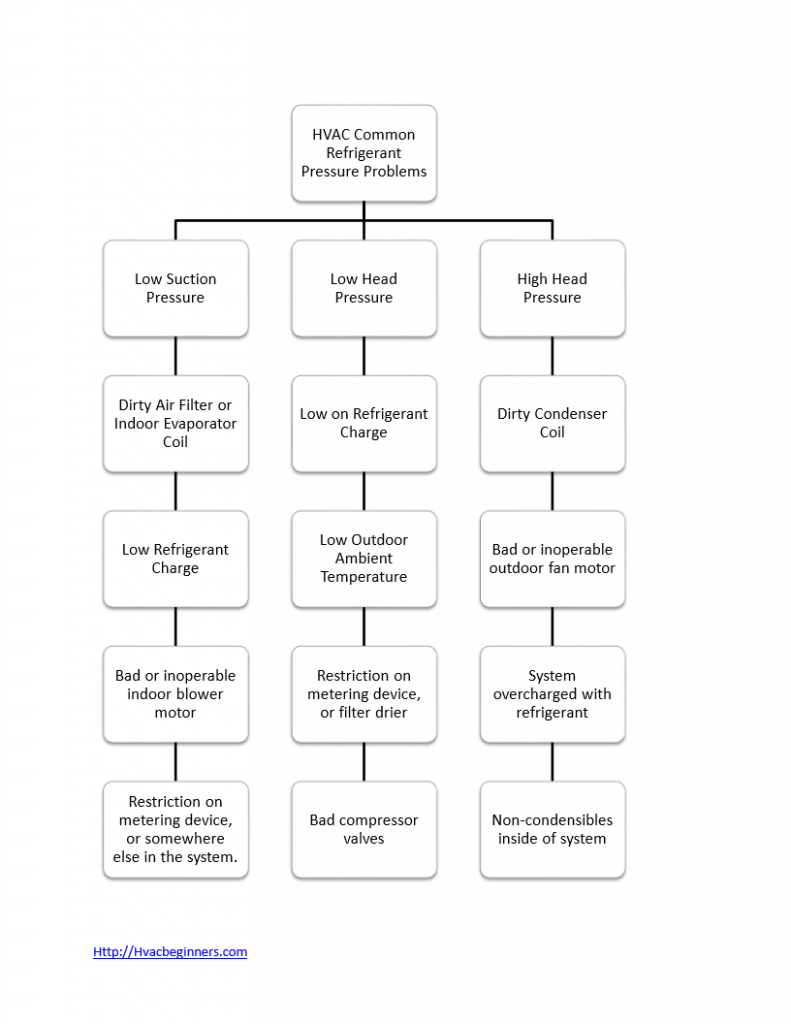

Charging a Home Air Conditioning System Flow Chart

Troubleshooting Refrigerant Charge to Determine a Bad TXV

- If your suction pressure is staying the same while adding refrigerant, and your head pressure is shooting up while the suction pressure is staying the same, your TXV valve is probably bad.

- If you do your homework and suspect that the TXV bulb lost charge, it’s probably a better idea, to just replace the bulb and valve. If you know your shit, then by all means, do what you think is best. This is what I do though.

- Should the TXV valve be located inside of the air handler, where it’s cool, proper insulation is not as important. Contact to the suction line is always important though.

- 10 and 2. Call the manufacturer though for optimal bulb placement.

What should my Subcooling and Superheat be?

- For subcooling a ballpark range may be somewhere inbetween 10-15 degrees F. For superheat it could be 12-20 degrees F. Check with the manufacturer though.

- Many units have a charging chart, behind the name plate on the condensing unit, use this first.

- Charge by superheat for fixed metering devices, and use subcooling for TXV’s, if your not sure check the manufacturer documentation.

- None of this means ANYTHING if your airflow isn’t up to manufacturer specs.

- Same goes with proper system sizing. Most units are undersized to reduce building cost. Most duct work is undersized for the same reason.

What should my pressures read on R-22 systems?

I get asked this all the time. From my experience normal R22 pressures may be somewhere around 70psi for suction and 240psi for head pressure. DO NOT use this as a rule of thumb or even a ballpark figure, there are too many variables that could change your R22 Pressures.

What should my normal operating pressures on 410a systems be?

R410a suction pressure may be around 120psi, and R410a head pressure may be anywhere from 225psi to 350psi. Many conditions could apply here, there’s absolutely ‘no’ set point pressure for 410a, r22, or anything else. Educate yourself on whats going on in the heat transfer process. Airflow, outdoor and indoor ambient temperature, equipment sizing, and tool calibration all have an extremely important role to answer this question accurately.

Whats Temperature Drop and Why should I care?

Temperature drop, or sometimes just called a TD, or Delta T, is when you measure the air temp coming into the evaporator coil, and subtract that from the air leaving the evaporator coil after a few feet. For 410a this should be around 16-18 degrees F. For R22 it may be around 17-21 degrees F.

A delta T reading may not be the most accurate way to measure a charge in a system, but it should help deciding whether you should hook up your gauges or not. This is also a method a homeowner can use to determine whether their air conditioner needs service or not.

Every time you hook up gauges you are taking refrigerant out of the system, even if it’s a little. Air conditioners are supposed to be tight sealed systems that don’t leak. Your hvac tech is hooking up gauges several times a year for maintenance, it’s losing refrigerant.

Lots of low pressure systems, such as wine coolers and commercial fridges and freezers, don’t have gauge ports for this reason. Once a Mitsubishi rep told me I shouldn’t ever hook up gauges to the ductless mini-splits they sell. That I should just take the temperature drop. Depending on the temperature drop, that will determine whether or not gauges need to be hooked up. Ask 10 of the best air conditioning techs out there what the best way is, and you’ll get different answers from all of them.

Compressor is Running but I’m reading Zero on my Gauges!?

Open up your service valves, they are probably shut. Yes I’ve seen this happen more than once….

Or, the hvac system is completely out of refrigerant, which means you have bigger problems. Find and fix that leak.

Best tip for troubleshooting refrigerant charge

The refrigeration cycle. Live, memorize, and learn more about it. If you don’t understand COMPLETELY how it works, then you are going to be pissing off a lot of customers, other techs, mentors, on a regular basis.

It shouldn’t matter if you are an Hvac installer, apartment maintenance technician, hotel tech, hvac service technician. You need to know the refrigeration cycle and understand it.

How often should an air conditioner need charged with refrigerant?

Remember that an air conditioner is a sealed system. If installation and repairs are done correctly, then the refrigerant should stay in the system forever. It should not have to be charged until mechanical or physical failure occur. Refrigerant leaks should be fixed properly prior to charging an air conditioner with refrigerant.

I have a 5ton R410. Outside air temp 95. Running for an hour, suction 120, head pressure between 315-350. Fluctuates. Why not steady head pressure. Unit is 6 years old. Cools the house good. Thanks

Could be a little air in the system. As well as many other things.