Electric heaters are common in many split Hvac systems where it doesn’t get so cold, and also apart of many heat pump systems, which they are often referred to as ’emergency heat’. Electric heaters typically cost more to run than heat pumps, but are necessary when temperatures get so cold outside that the heat pump may not be able to keep up with the temperature. I will be explaining the basic wiring of an electric heater only today, so that those who need a little more hvac training on the subject can do so here. Note to read my disclaimer, and unless you have at least 2 years in hvac school along with 2-3 years of hvac apprenticeship training you should not attempt or rely on this diagram at home, this is for informational purposes only, this is also not at all intended for field use! If you are in the field refer to the manufacture wiring diagram.

Electric heaters are common in many split Hvac systems where it doesn’t get so cold, and also apart of many heat pump systems, which they are often referred to as ’emergency heat’. Electric heaters typically cost more to run than heat pumps, but are necessary when temperatures get so cold outside that the heat pump may not be able to keep up with the temperature. I will be explaining the basic wiring of an electric heater only today, so that those who need a little more hvac training on the subject can do so here. Note to read my disclaimer, and unless you have at least 2 years in hvac school along with 2-3 years of hvac apprenticeship training you should not attempt or rely on this diagram at home, this is for informational purposes only, this is also not at all intended for field use! If you are in the field refer to the manufacture wiring diagram.

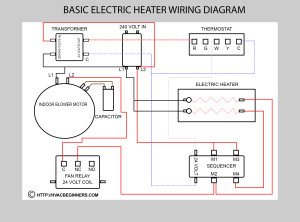

This is just to give you an idea of a typical electric heater setup in a split air conditioning and heating system. Notice that this one has a relay on it that has NO and NC terminals. Other units may have a computer board that has NO and NC terminals, others may have a more advanced type of board in them, but for the purpose of today’s training we are going to use this diagram. The NC terminal means that there is always going to be power going through that relay to the sequencer.

This is just to give you an idea of a typical electric heater setup in a split air conditioning and heating system. Notice that this one has a relay on it that has NO and NC terminals. Other units may have a computer board that has NO and NC terminals, others may have a more advanced type of board in them, but for the purpose of today’s training we are going to use this diagram. The NC terminal means that there is always going to be power going through that relay to the sequencer.

But the sequencer is not energized until it gets a call for heat from the ‘W’ terminal on the thermostat. The 24 volt ‘common’ wire is always going to be live going into the sequencer, when the thermostat get a call for heat, ‘W’ is energized, which closes the circuit on the sequencer, which will complete the connection to the blower and the first stage of heating. Depending on what kind and what stage sequencer you have, the second set of contacts on the sequencer may open 30-60 seconds after the first set opens. In this diagram I am using a 2 Pole 24volt coil heat sequencer.

So if you are out in the field trouble shooting electric heat, the first thing I would check is if I was getting 24 volts to the sequencer, by putting my test leads on common and white low voltage line going into the sequencer, which should read around 24 volts if its energized. Next test I would check is if I was getting the high voltage coming into the unit, if so, I would put my test leads between m1 and m2, and should read 0 volts, as well as between M3 and M4. If I am reading 120-240 volts (approx.) between either M1 and M2, or M3 and M4 (after waiting a couple of minutes), then I know that I have a bad sequencer (very common).

Next thing I would check if the sequencer checks out would be my limit switches, which are right at the heater elements itself. Most limit switches should normally be closed, sometimes these go bad and will constantly close and open, and you will here the sequencer, dc relay (not pictured), or contactor (not pictured) constantly open and close. If this is the case then check those limit switches.

The final thing to check is if your limit switches check out is to check the continuity though the 1, 2 or 3 heater elements. Should an element wire be broken, you will either have to restring or just replace the entire heater. Here’s a tip when working on electric heaters. Secure the power and just pull the entire heater out if you are replacing a faulty part or verifying that an element has broken.

Notes: Not all electric heaters use sequencers. Some will used computerized circuit boards, 2 pole contactors, DC relays or any combination of the 2. The principle is the same, there is going to be something stopping that circuit from being complete. When ‘W’ is energized, that is going to shut the contacts in the sequencer, board, or relay to complete the high voltage circuit. Once you understand this, it’s smooth sailing.

How do you check electric heat? With an amp clamp of course. if you have a 5kw you can expect it to draw 14-20 amps, 10kw 35-42 amps, 15kw 58-65 amps, this of course is only based on high voltage between 208-240 volts, the amps WILL vary depending on voltage, as will the KW size.

Another way to check if your electric heater is working is by temperature rise. I have found that you typically get a 20-30 degree difference from return to supply, depending on what size heater you have and whether or not your temperature probe is picking up the heating elements radiant heat.

HELP! I have same system as your pictorial above, but with two sequencers. How do I wire it together?

Thank you for your diagram, I had a problem of the blower running continuously and after having two shatty heating and air company workers slinging parts at it ,I pulled the element out and found the problem myself ,Thanks